In this article we are going to find out how Rapid Energy can support Biodigester Plants by providing temporary heating solutions.

We are all trying to play our part in saving the environment by reducing the amount of waste we create, with many households trying their best to limit the amount of food they throw away. However, there is still tonnes of food thrown away each year. Biodigester plants provide an environmentally sustainable solution to the challenging question of how to best deal with that waste.

Biodigester Plants process tonnes of household and industrial waste each year and turn it into renewable energy. The process is called Anaerobic Digestion.

Anaerobic Digestion is not new, it has a long history, dating back to 1859 when the first known Anaerobic Digester was built. The technology used in Anaerobic Digesters today is actually very similar to what it was in the early 1900s.

There are now 579 anaerobic digesters in operation in the UK, 88 of these are biomethane to grid plants. There are a further 331 Anaerobic Digestion projects currently under development.

What are the benefits of Anaerobic Digestion?

Anaerobic Digestion reduces the amount of waste sent to landfill, this in turn reduces greenhouse gas emissions.

These are huge benefits, however there are other benefits to agricultural and industrial businesses who invest in Anaerobic Digestion.

Following a commitment made by the UK Government in 2010 to work towards a zero waste economy, a strategy was introduced in 2011 to increase energy through waste.

Financial incentives were made available to businesses to encourage them to divert waste from going to landfill sites. This has caused a significant increase in the number of Biodigestion Plants in operation in the UK today.

Using an Anaerobic Digester means businesses can recycle their own waste and cut their carbon footprint. The energy they produce can be used onsite and in local factories and buildings which can cut their costs significantly too.

Businesses are constantly making themselves greener and implementing processes to help protect the environment. This shows good company values and can enhance a businesses reputation.

What goes into an Anaerobic Digester?

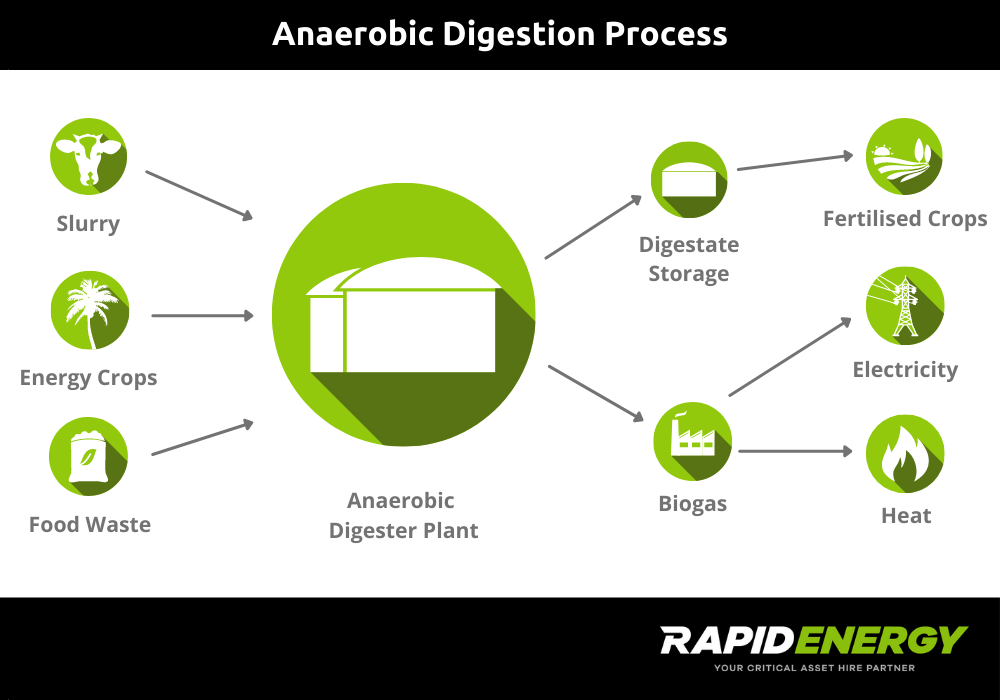

There are a number of organic materials that go into an Anaerobic Digester, these are known as feedstocks.

Sewage Sludge and Farm Manures and Slurries – This was the original feedstock used in Anaerobic Digesters.

Food Waste – More and more households are now separating their food waste from their other household waste. This is then transported to Biodigestion Plants.

Purpose Grown (Energy) Crops – Farmers are now growing crops with the sole purpose of using them in Anaerobic Digesters. The Government is also providing grants to farmers for this purpose – click here to learn more.

What does an Anaerobic Digester produce?

Anaerobic Digesters produce Biogas, this is a mixture of methane and carbon dioxide. Biogas is used to provide heat and electricity. As mentioned before this can be used onsite and in local factories and buildings.

Carbon Dioxide can be removed from the Biogas, leaving Biomethane which can be injected directly into the National Grid.

Once the gases have been removed a liquid substance called Digestate is left behind, the great news is that this is a valuable nutrient rich fertiliser.

How can we help?

Temperature is critical to Anaerobic Digestion, as is the need to prevent the process from being interrupted. Our heating and hotwater contingency plans are designed to reduce the downtime of heating and/or hot water to a facility or plant. We conduct a detailed survey and scope of works to determine what’s required to deliver and commission a packaged boiler on your site.

If your existing boiler plant is showing signs of malfunctioning or if you are in the process of conducting a planned boiler shut down for maintenance, we can help. We can scope the correct packaged boiler for your facility, and will work closely with your team or contractors to deliver a temporary heating solution on time.

We can also react very quickly in an emergency. If your boiler plant has failed, we can be onsite within hours. We have previously delivered, installed and commissioned a temporary boiler within 24 hours for a client that needed access to both heating and hot water.

We can also design and build a highly efficient and cost effective long term temporary boiler for your Biodigester Plant.

Our packaged boiler capacity begins at 150kW right up to 2000kW (2MW) for any of the solutions mentioned above. You can view our entire range of boilers here.

Hydrotreated Vegetable Oil (HVO) – with the focus around greener solutions, we are pleased to be able to provide the option of using this high-quality renewable diesel in our packaged boilers. It is a form of renewable diesel and is produced from renewable and sustainably sourced vegetable fats and oils. We talk more about HVO in our blog, click here to learn more.

If you’re exploring your options or are indeed putting a boiler contingency plan in place for your Biodigester Plant, speak to a member of our team today.