Project Overview

When the maintenance manager of a leading industrial biodigester facility in Dartford faced a sudden boiler failure, the stakes were high. An industrial biodigester facility is a plant that processes organic waste or sludge using microbial digestion to generate biogas, reduce waste, or produce useful byproducts, requiring precise temperature control for efficiency. To learn more about how they operate, click here.

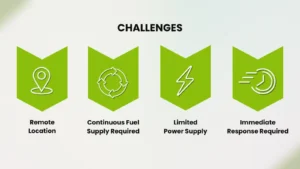

Consequently, without a functioning heating system, the biodigester’s operations were at risk of severe disruption, impacting productivity and efficiency. To avoid prolonged downtime while awaiting replacement parts, the facility needed a reliable, temporary heating solution- fast.

Understanding the urgency of the situation, the facility’s maintenance team quickly assessed their requirements and sought a partner who could deliver a temporary heating solution whilst awaiting replacement parts. They reached out to Rapid Energy, knowing that swift action was critical to maintaining operations.

0800 464 7025 Available 24/7

0800 464 7025 Available 24/7