-

-

0800 464 7025 Available 24/7

-

-

0800 464 7025 Available 24/7

In the construction industry, timing is everything and staying ahead of schedules often requires innovative solutions. On one of our client’s recent large-scale projects, expediting the screed drying process became a critical factor for success. To meet the challenge, we deployed multiple Mobile Electric Boilers, designed specifically with the construction industry in mind.

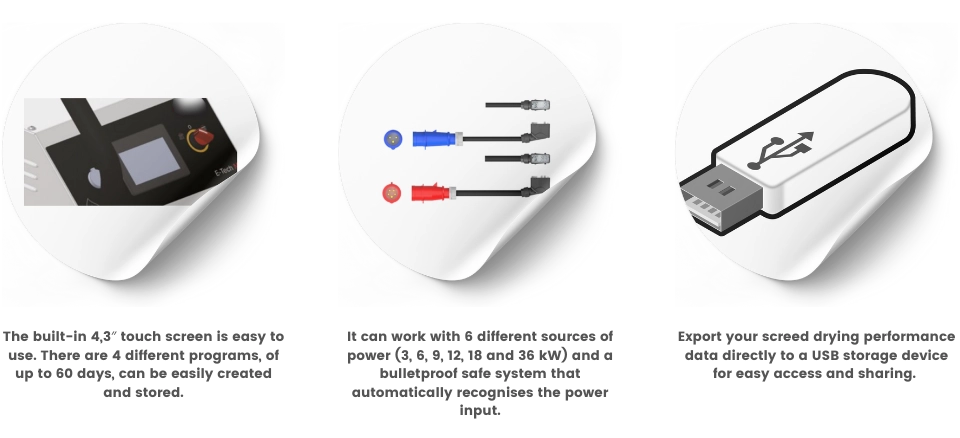

These versatile Mobile Electric Boilers, equipped with a built-in 4.3″ easy-to-use touch screen, provided unparalleled efficiency and control. Trolley-mounted for effortless positioning, they seamlessly adapted to the dynamic demands of the site.

With compatibility across six power inputs (3, 6, 9, 12, 18, and 36 kW) and a bulletproof safety system that automatically recognises the power source, they delivered reliable performance without compromise. Using 30 x 12kW units, we efficiently met heating requirements across multiple blocks on this expansive, London based construction site, ensuring the project stayed on track and on schedule.

A significant obstacle was the limited power availability on-site, which was inadequate to support the large number of electric boilers deployed for this project. Addressing this challenge required an efficient power solution to ensure continuous productivity.

The on-site team initially lacked the technical expertise to install and manage the intricate network of mobile electric boilers. To overcome this, we implemented a comprehensive training approach:

To ensure optimal delivery and uninterrupted operation of the system, careful planning went into the placement of the generator and fuel tank. We conducted a detailed site assessment to develop a precise strategy, that included:

The seamless integration of our modern Mobile Electric Boilers, expert training, and strategic equipment placement led to a highly successful project outcome. The on-site team not only gained the technical expertise to independently manage the installed systems but also developed a stronger and more collaborative working relationship with the technical staff. This newfound confidence and capability translated into smoother operations and enhanced efficiency, earning positive feedback from all stakeholders involved.

Our customer centric approach to utilising temporary electric boilers not only accelerated the screed drying process on this complex construction site but also equipped the on-site team with valuable skills and knowledge to manage the system effectively. By combining strategic equipment coordination with expert guidance, we demonstrated our unwavering commitment to providing comprehensive, client-focused solutions tailored to the unique demands of large-scale projects.

“Outstanding Service! Hannah has been great to work with, providing all the information needed to get the boilers, leads, and generator to the site, along with technicians who explained how everything works. A complete 5-star service.”