The construction industry is constantly under pressure to meet targets quickly and efficiently. One aspect of construction which can slow the process down, is drying screed. The time it takes for the screed to dry using the underfloor heating can impact the success of the project. For this reason, many contractors choose to speed up the screed drying process so that projects can be completed faster.

Benefits of speeding up the drying of screed

- Reduces delays – allowing contractors to meet deadlines and keep their clients happy.

- Saves on time – less time needs to be allocated to this part of the process.

- Save on costs – projects can be completed in a shorter time frame.

What is screed?

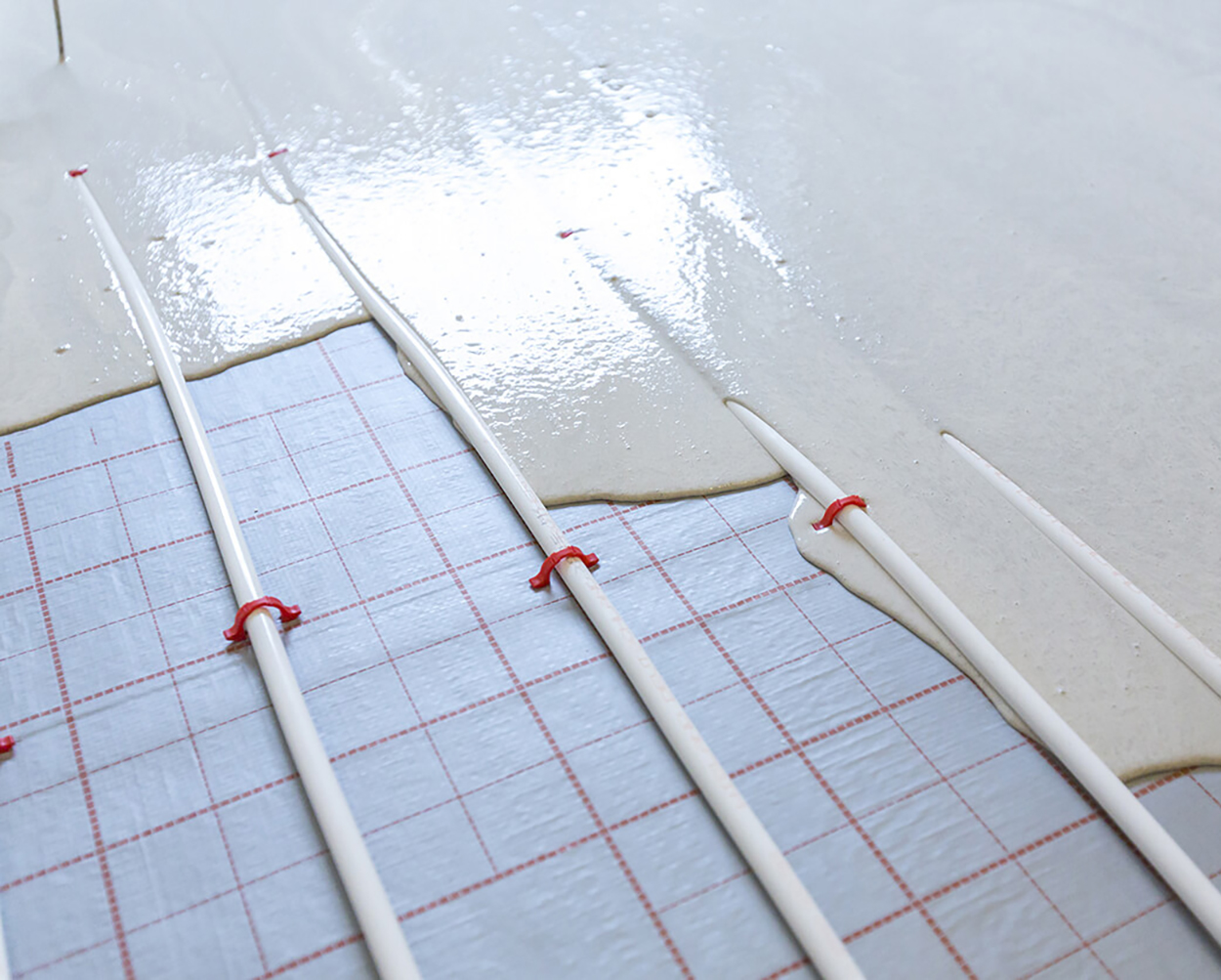

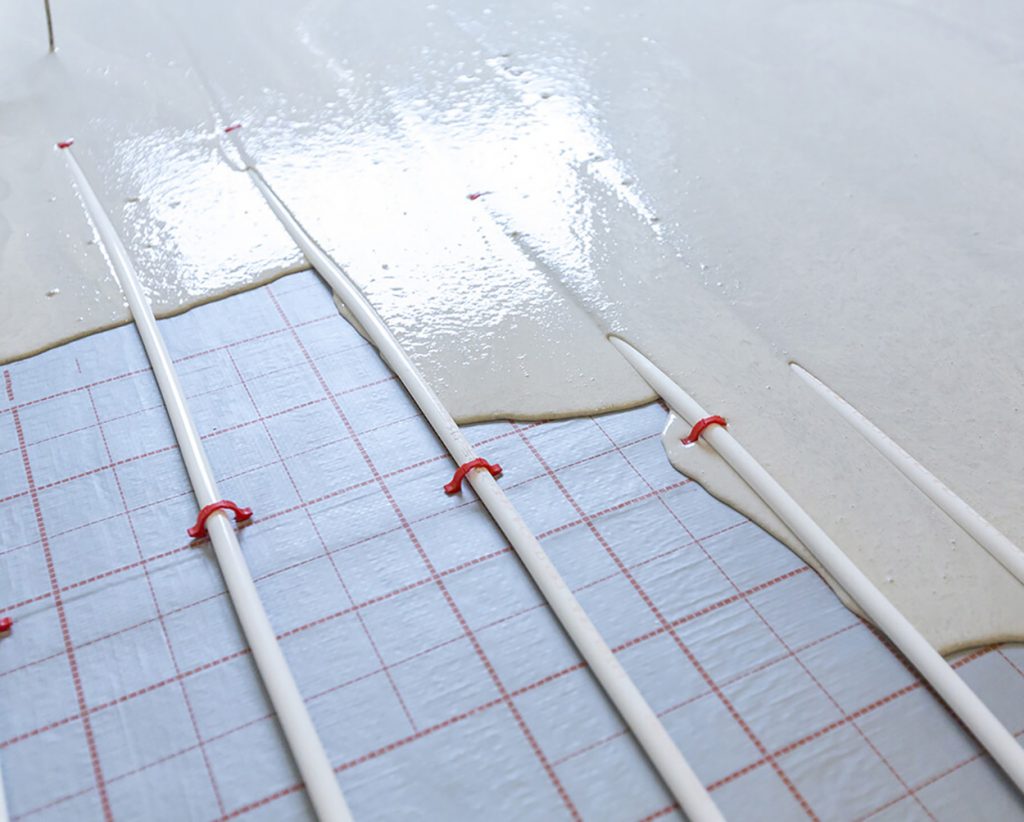

Screed is a thin layer of material which is laid over a concrete subfloor. Traditionally, screed is made from sharp sand and cement, making it similar to concrete. The purpose of screed is to provide a flat and smooth surface which other finishing materials can be laid on top of. This includes tiles, carpets or floorboards. Floor screed is used to cover and bury underfloor heating pipes, helping to deliver the best heating performance.

What is underfloor heating

Underfloor heating is a heating system where pipes are installed under the floor. It warms the room from the ground up which is less demanding on a boiler than a traditional radiator system. This is because underfloor heating has a lower operating temperature than radiator systems. The system works by distributing warm water through a circuit of pipes beneath the floor. The heat is monitored and controlled by thermostats which maintain a consistent and comfortable temperature.

The different types of screed flooring

Unbonded screeds are not bonded directly to the base but instead are adhered to polythene laid on top of the concrete base.

Bonded screed is bonded onto the substrate by slurrying bonding to the concrete substrate. This is often used when heavy loading is anticipated.

Floating screed is laid over a layer of insulation with a slip membrane over it which separates the insulation from the screed.

Often, screed modifications and additives are used to change how the screed works.

A hydraulic binder is a substance which chemically reacts with water, with the ability to agglomerate other solid materials.

A plasticiser is a substance added to a material to make it more flexible and increase its plasticity and decrease its viscosity.

Aluminium based cement is used to decrease the setting time.

Polypropylene fibres can help control cracking and polymers may be added to give the screed chemical and water resistance properties.

The difference between traditional and free-flowing screed methods

Traditional screed methods often take longer but are also deeper and usually more economical. Traditional floor screed is applied with a straight-edged float and finished with a trowel.

Free-flowing speeds are shallower but are also quicker to lay. It can be applied with a pump as it has a free-flowing consistency.

Temporary Electric Boilers are the solution

A mobile electric boiler is the best solution for screed drying via underfloor heating. Rapid Energy’s electric boilers are especially useful as they are trolley mounted and can be easily moved around the site and connected directly into the buildings manifold. The temperature of the boiler can easily be adjusted to accommodate the climate of the building, square meterage and the type of screed being used. These boilers have the power and control needed to aid screed drying during construction as well as heating when construction is complete.

In September 2023, Rapid Energy invested in a new fleet of mobile electric boiler, designed and built specifically for speeding up the process of drying screed.

It’s a smart and modern machine – The built-in 4,3″ touch screen is easy to use. There are 4 different programs, of up to 60 days, can be easily created and stored. The results are available for download via USB, to create your own report of the screed drying process.

The 3-36kW MEB has 1 plug-in – It can work with 6 different sources of power (3, 6, 9, 12, 18 and 36 kW) and a bulletproof safe system that automatically recognises the power input. No matter which power supply you find on the next construction site, the 3-36kW MEB will do the job. Click here to learn more about the 3-36kW MEB, click here.

Which capacity and connection type is right for you?

If you have underfloor heating installed but no boiler in place, you will need to identify the correct connection type and capacity which is required. An efficient, reliable electric boiler is recommended. It would also need to be trolley mounted, making it easy to manoeuvre into position.

We have 4 different capacity electric boilers that our customers can hire. Depending on the size square meterage and the type of electric connections you have available onsite, will determine which boiler/s that you hire. Our 15kW electric trolley mounted boilers use a Single Phase, 63 Amp Socket. Our 22kW uses a 3 Phase 63 Amp Socket and the 36kW and 40kW boilers use a 3 Phase, 32 Amp Socket. Customers will need to speak to an expert at Rapid Energy to determine how many units are required for the job in question.

Ensure you understand screed the drying process. Professionals understand the screed drying process and can carry out the procedure efficiently to avoid any issues.

Potential Issues Associated with Floor Screeds

It is important that you understand the screed drying process. If you are unsure, it is always best to call in the professionals, who understand the screed drying process and can carry out the procedure efficiently to avoid any issues.

If the screed process is carried out incorrectly, then problems can occur. The process of drying involves water leaving a substance, which can lead to problems with the screed.

- With artificial drying, there is an increased risk of cracking occurring, which is why the process must be carried out by professionals

- Curling can also occur with thinner screeds as they dry quicker and can happen at internal angles

- Shrinkage happens when water is removed, although some screeds have water-reducing properties

At Rapid Energy, our fleet of equipment includes electric boilers, which are available to hire to assist with the screed drying process. Our mobile boilers are trolley mounted for ease of use and ensure that delays are avoided. To learn more about our equipment, get in touch today on 0800 464 7025 or complete form below.