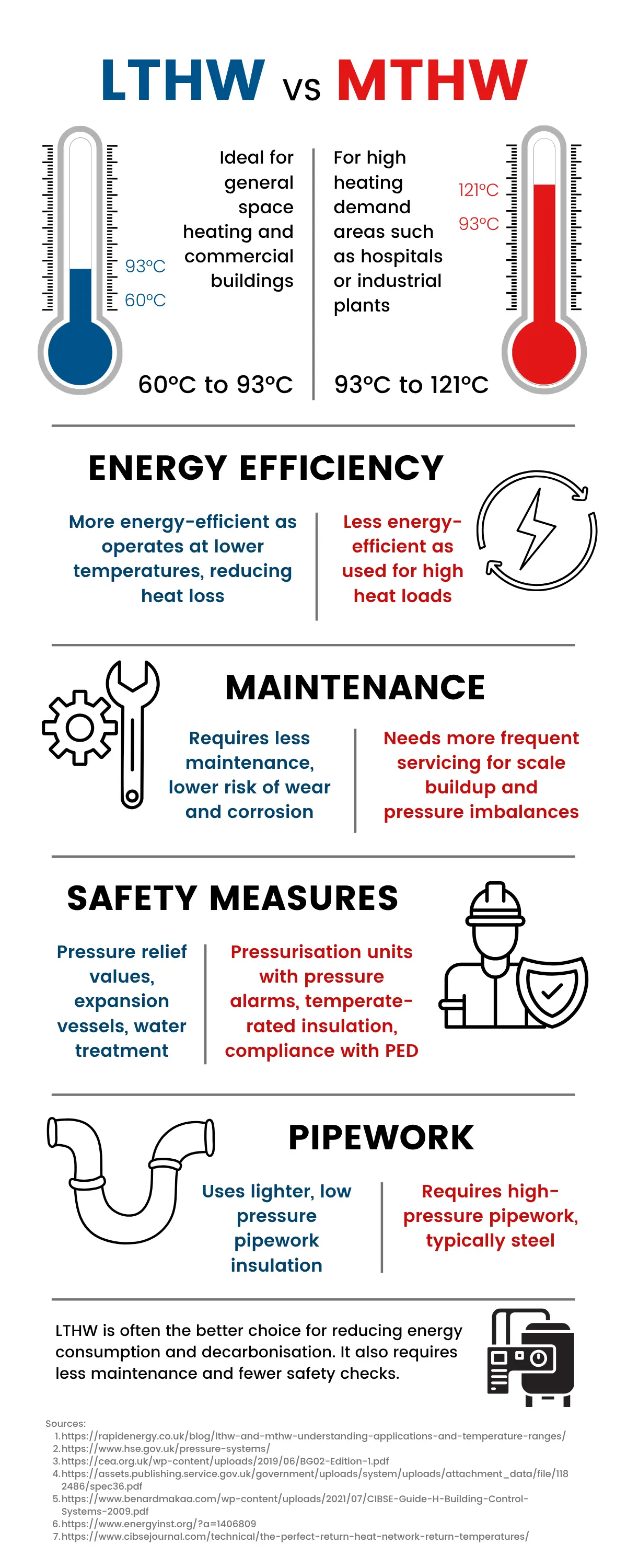

Whether you’re dealing with a planned boiler shutdown or an urgent heating failure, understanding the difference between Low Temperature Hot Water (LTHW) and Medium Temperature Hot Water (MTHW) systems is key to making the right decision quickly.

At Rapid Energy, we provide expertly engineered temporary heating solutions across commercial and industrial environments. The right temperature system is the foundation of any successful deployment.

Here’s what you need to know…

If you want to share this infographic, you can embed this HTML code.

<a href="https://rapidenergy.co.uk/blog/lthw-vs-mthw-what-you-need-to-know/" target="_blank">

<img src="https://rapidenergy.co.uk/wp-content/uploads/2025/06/LTHW-vs-MTHW-infographic-scaled.webp" alt="A graphic showing the difference between Low Temperature Hot Water (LTHW) and Medium Temperature Hot Water (MTHW)" style="max-width:100%; height:auto;" />

</a>

<p style="font-size:12px;">Via: <a href="https://rapidenergy.co.uk target="_blank">Rapid Energy</a></p>Temperature and Performance

- LTHW systems operate between 60°C and 93°C, suitable for general space heating and commercial buildings.

- MTHW runs hotter, typically between 93°C and 121°C, and is used where higher heat loads are required, such as hospitals or industrial plants.

The choice depends on your building’s heat demand, system pressure rating, and application type.

Learn more about the temperature ranges.

Energy Efficiency and Sustainability

LTHW systems tend to be more energy-efficient, especially when combined with condensing boilers or renewable sources like air source heat pumps. Their lower operating temperatures allow for reduced heat loss, improved boiler performance, and alignment with low-carbon heating strategies.

There’s a clear move toward low-temperature heating, driven by:

- Decarbonisation targets

- Improved building insulation

- Adoption of renewables

- Efficiency standards (e.g. CIBSE, SBEM)

LTHW is more compatible with these evolving standards, making it increasingly popular in both new builds and system upgrades.

MTHW, while less efficient, is better suited for high thermal loads where rapid heat delivery is a priority, such as process heating or large-scale heating networks.

Using LTHW Systems in Large Commercial Buildings

Modern LTHW systems, when designed correctly, can comfortably heat large commercial spaces. Advances in zoned heating and high-efficiency distribution mean LTHW is now a viable option for many buildings previously reliant on MTHW.

However, in buildings with particularly high heating demand, MTHW may still be the better fit.

Switching from MTHW to LTHW

Organisations aiming to reduce energy use or decarbonise may explore converting MTHW systems to LTHW. This is possible, but it requires a thorough review of:

- Heat exchanger and emitter capacity

- Pipe sizing and insulation

- Required flow temperatures

Rapid Energy can assess the viability of such a transition and support temporary solutions during retrofit work.

Impact on Pipework and System Design

Temperature range directly affects system materials:

- MTHW systems require high-pressure-rated pipework, typically steel, with thicker insulation and specialist fittings.

- LTHW systems can often use lighter, more cost-effective materials, including certain plastics, due to their safer operating conditions.

This makes LTHW systems easier and often cheaper to install and adapt.

Maintenance Considerations

LTHW systems require less maintenance overall, thanks to:

- Lower wear on valves and pumps

- Reduced scaling and corrosion risk

- Simpler control and expansion arrangements

MTHW systems, by contrast, require more regular servicing and rigorous safety inspections, particularly on components operating under pressure.

Safety Measures

Both systems require appropriate safety precautions, but the risk level increases with temperature and pressure.

LTHW Safety Measures:

- Pressure relief valves (PRVs)

- Expansion vessels or pressurisation units

- Low-pressure pipework insulation

- Water treatment to prevent corrosion and biofilm buildup

MTHW Safety Measures:

- High-rated PRVs and pressure controls

- Pressurisation units with pressure alarms

- Steel or reinforced pipework systems

- Temperature-rated insulation

- Full compliance with the Pressure Equipment Directive (PED)

All Rapid Energy units are tested to meet the latest safety and compliance standards, including documentation for H&S and insurance purposes.

Integration With Existing Systems

Our LTHW and MTHW plant rooms are engineered for seamless integration into your existing infrastructure. Whether your site uses:

- Plate heat exchangers

- Direct pipework connections

- Buffer vessels or hybrid zones

We provide the right connectors, controls, and commissioning support to get your system up and running fast.

Boiler Hire Options

We offer flexible and scalable temporary boiler solutions for both LTHW and MTHW applications, including:

- Packaged Boilers – all packaged boilers in our fleet are LTHW, except for our 2MW unit, which is capable of delivering MTHW. We offer both gas and oil packaged boilers.

- Slimline Boilers – Compact and efficient LTHW gas and oil boilers

- Electric Boilers – Zero-emission LTHW systems

All units are available for emergency hire, planned outages, or long-term site support.

At Rapid Energy, we know that temperature control is critical to keeping operations safe and productive. Our team of engineers will guide you to the right system, whether LTHW or MTHW, and deliver fast, compliant, and expertly supported boiler hire when and where you need it.

Whether you’re managing a hospital, data centre, industrial site or residential building, we can select the right heating system for your site.

Call us today on 0800 464 7025 or email us at hire@rapidenergy.co.uk.