In the world of construction and flooring, screed plays a vital role in delivering a level, load-bearing surface ready for final floor finishes. However, a common mistake made on-site is misunderstanding the distinct processes of drying and curing, both of which are crucial to the success of a screed installation. These processes may seem similar, but they serve very different functions and require different conditions to be effective.

Getting these steps wrong doesn’t just delay your project; it risks structural integrity, causes surface defects, and may lead to long-term flooring problems.

In this blog, we’ll explain the difference between drying and curing of screed, why each stage matters, and how temperature control equipment, like Rapid Energy’s electric boilers, can support fast, safe screed drying.

What Is Screed?

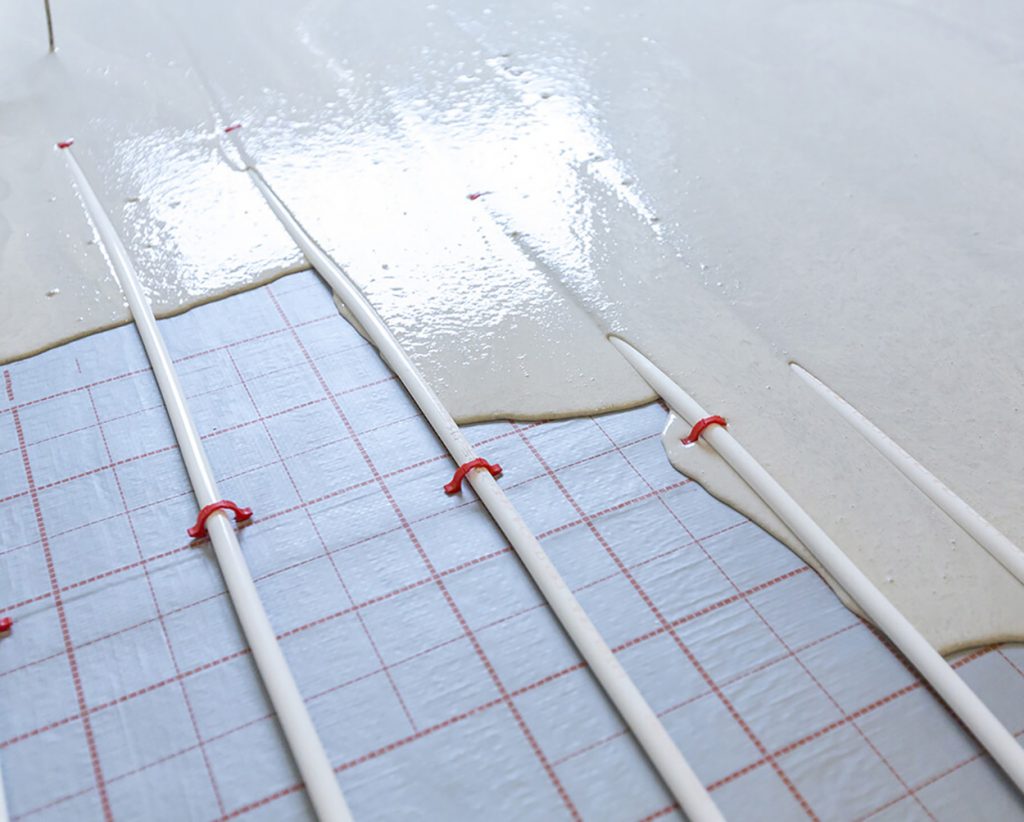

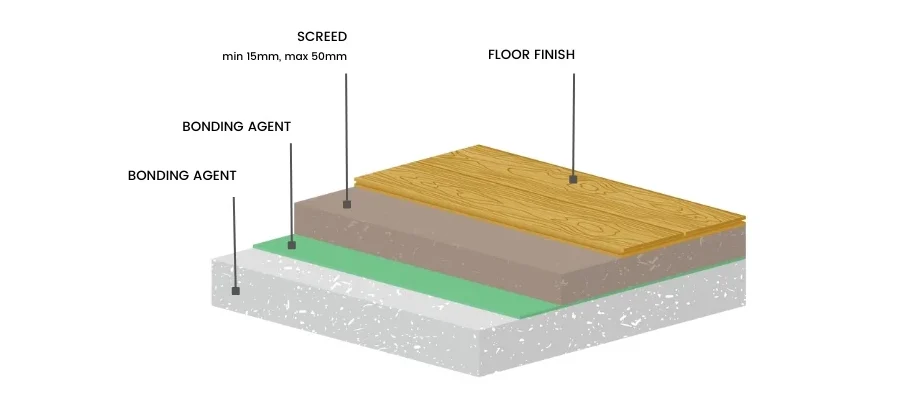

Screed is a layer of material, typically a cementitious mix, laid over a concrete subfloor to create a smooth, level surface for floor finishes such as tile, carpet, vinyl, or resin. It may also be used to encapsulate underfloor heating systems or provide a thermal mass.

There are several types of screeds, such as traditional sand and cement, liquid screeds (anhydrite or calcium sulphate), and polymer-modified systems. Each has different curing and drying profiles. For a detailed overview, explore our comprehensive guide to different types of floor screed.

Curing Screed: The Early Stage of Strength Development

Curing is the initial chemical process that occurs after screed is laid. It allows the cement binder to hydrate (react with water), gaining structural strength and integrity. This process typically takes around 7 days, though it can vary based on the mix and site conditions.

Why Curing Matters:

- Ensures the screed develops optimum strength and durability.

- Prevents early-age cracking and surface dusting.

- Improves resistance to wear and future floor load-bearing.

Best Practices for Curing:

- Moisture retention is key- use plastic sheeting or curing membranes.

- Avoid forced drying during this phase.

- Maintain temperatures between 5°C and 30°C for effective hydration.

Premature drying before curing can cause irreversible damage. Screeds must be protected against wind, direct sunlight, and frost. For practical guidance, click here.

Drying Screed: Reducing Moisture Content Post-Curing

After curing, the screed still contains a significant amount of moisture. Drying is the gradual process of removing this excess water to prepare the screed for floor covering installation.

Key Facts About Drying:

- Occurs after curing, over several weeks depending on thickness and environment.

- A screed is typically dry when residual moisture content falls below 75% RH (relative humidity).

- Failure to allow full drying can lead to adhesion failure, mould growth, and warped floor finishes.

Drying time depends on:

- Type and thickness of screed.

- Ambient temperature and ventilation.

- Use of dehumidifiers or heating equipment.

Explore different drying strategies.

Drying vs Curing: Understanding the Differences

Many project delays and failures stem from treating drying and curing as one and the same. Here’s how they differ:

When you separate these processes and plan accordingly, you avoid unnecessary rework and ensure your floor performs as expected.

How Relative Humidity (RH) Affects Drying

Monitoring relative humidity is one of the most effective ways to determine screed readiness. If RH is too high, it indicates retained moisture that can compromise floor finishes. Environmental RH and screed RH are not the same, but both need to be managed.

Learn more in our guide.

The Role of Temporary Heating Solutions in Drying Screed

Drying screed naturally can be slow, especially in colder months or poorly ventilated areas. In time-critical or climate-sensitive projects, using mobile heating equipment can dramatically speed up the drying process safely and effectively.

Why Heating Helps:

- Increases air temperature to encourage evaporation.

- Prevents drying delays caused by winter conditions or site limitations.

- Supports project timelines without compromising screed quality.

Important Note: Heating must be controlled. Overheating too early or applying uneven heat can cause cracking or differential drying. Always follow screed supplier guidelines.

Choosing Rapid Energy:

At Rapid Energy, we understand that time is money on construction projects. That’s why our fleet includes mobile electric boilers, ideal for assisting with the screed drying process.

Available in 3kW to 36kW outputs, our electric boilers are:

- Trolley-mounted for easy positioning on-site.

- Fast to install and operate.

- Quiet, emission-free, and efficient.

- The built-in 4,3″ touch screen is easy to use.

- There are 4 different programs, of up to 60 days, can be easily created and stored.

- The results are available for download via USB, to create your own report of the screed drying process.

Because it might be operating for several days without surveillance and because screed drying requires an extra care on temperature control, it makes no compromise on safety.

A series of devices and configurations, including an interruption protocol, will let your screed dry in the optimal way and will let you go to your next construction site in complete confidence.

While being an intelligent and accurate instrument, it’s also robust, ready to face the hardest working conditions. A sturdy safety bar on the front protects it from shocks.

From heating for screed drying to emergency HVAC backup, our clients trust us when performance cannot be compromised.

Contact Rapid Energy today on 0800 464 7025 for expert advice and a tailored equipment hire plan.