In most construction projects, concrete floors are typically covered with a layer of screed to create a smooth, level surface before installing floor coverings like tiles, carpet, or timber. While screeds are sometimes left exposed in places like warehouses, in most cases, they serve as an underlayment for finishing materials. Screeds are usually made from a mixture of sand and cement, often with added fibers and other additives to improve performance.

With various types of screeds available, selecting the right one for a specific project can be challenging. In this article, we’ll explore the different types of screeds, their unique properties, optimal thicknesses, and the applications they are best suited for.

Understanding Screed Composition

Screeds are typically made from a mixture of cement and sand, with a common ratio ranging from 1:3 to 1:4.5. Some screeds also include additives that enhance their strength, drying time, or other characteristics. For example, certain additives can improve a screed’s durability or reduce drying time, making it more suitable for time-sensitive projects.

Self-compacting screeds are another option, designed to be pumped through a hose and leveled with a dappling bar. These screeds are often made from calcium sulphate-based compounds, allowing for faster and more efficient installation over large areas. However, care must be taken to ensure they dry completely, as incomplete drying can lead to performance issues.

It’s important to note that screeds made from calcium sulphate must be installed with a slight slope to prevent water from pooling, which makes them unsuitable for wet areas such as around swimming pools, in steam rooms, or in saunas.

All types of screeds will naturally expand and contract as they cure, so expansion joints or crack-inducing cuts must be installed to prevent cracking. Other factors like durability, load-bearing capacity, and surface finish requirements will determine the most suitable type of screed for any given project.

Let’s now take a closer look at the different types of screeds and their specific uses.

Types of Screeds

1. Bonded Screed

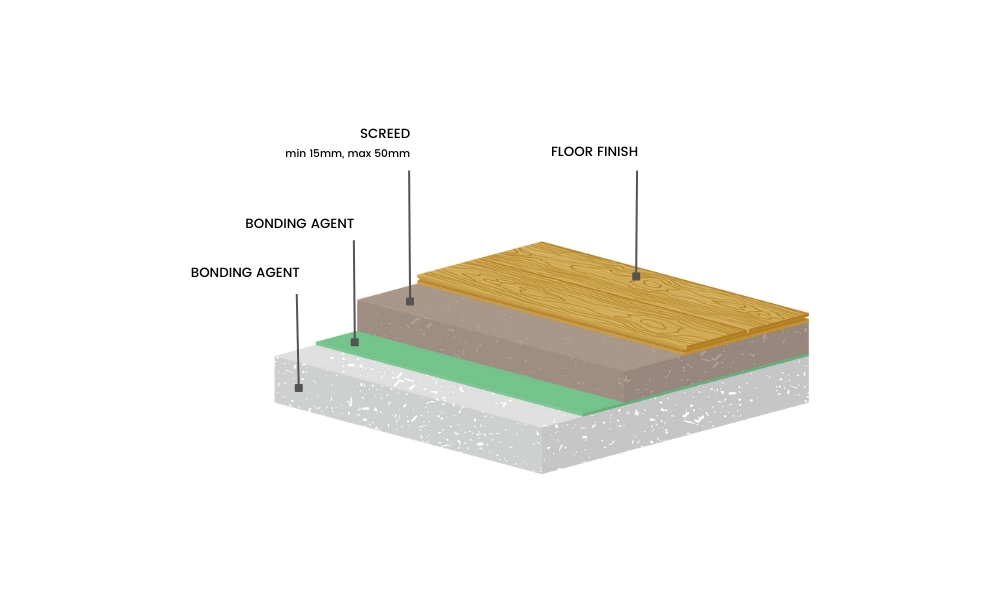

In bonded screed installations, the screed layer is fully bonded to the substrate using a bonding agent or primer. This method is typically used for thinner screeds in high-load areas where space is limited and a strong, direct bond to the base is necessary.

Thickness: Cement and sand bonded screeds are usually installed at a thickness of 25 to 40 mm. Some flowing screeds made from calcium sulphate can be laid as thin as 12 mm.

Applications: Bonded screeds are ideal for heavy-duty environments like car parks and driveways. They are also used in underfloor heating systems that incorporate cast-in water pipes.

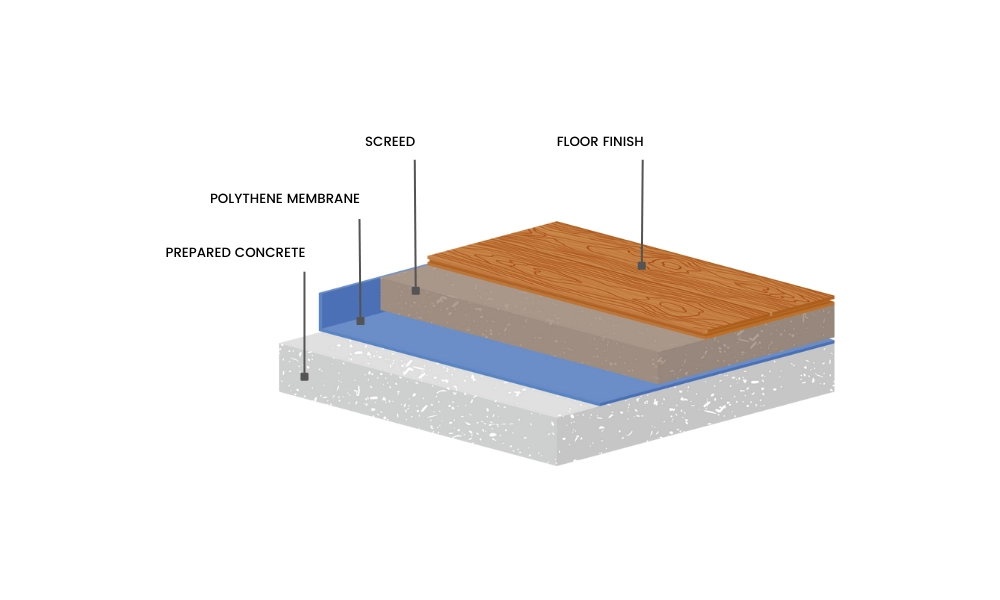

2. Unbonded Screed

Unbonded screeds are laid over a damp proof membrane (DPM), which is installed directly on top of the concrete base. The DPM prevents rising damp from affecting the screed layer.

Thickness: A cement and sand unbonded screed typically requires a minimum thickness of 50 mm, while calcium sulphate screeds can be laid at around 30 mm.

Advantages: Since the screed is not directly bonded to the concrete base, it is less affected by shrinkage or settlement issues. However, care must be taken to avoid curling, which can occur when screeds dry too quickly.

Applications: Unbonded screeds are commonly used in similar settings to bonded screeds, especially when a damp proof barrier is required.

3. Liquid or Flow Screed

Liquid or flow screeds, also known as self-compacting screeds, are rapidly gaining popularity in the industry due to their ease of installation and fast drying times. These screeds are suitable for light pedestrian traffic within 24 to 48 hours and can be loaded after seven days.

- Types: While many flow screeds are made from calcium sulphate, some use cement and a copolymer to achieve a concrete-like finish.

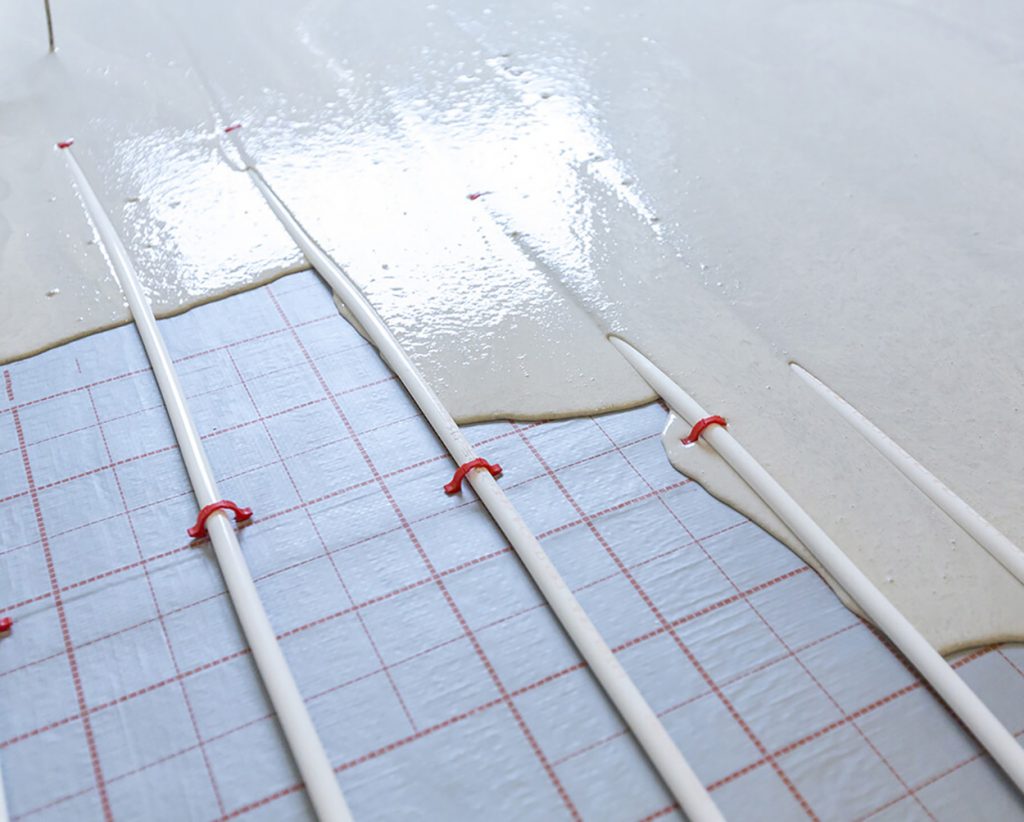

- Applications: Flow screeds are frequently used in underfloor heating installations, where they help create a smooth, even surface that efficiently conducts heat.

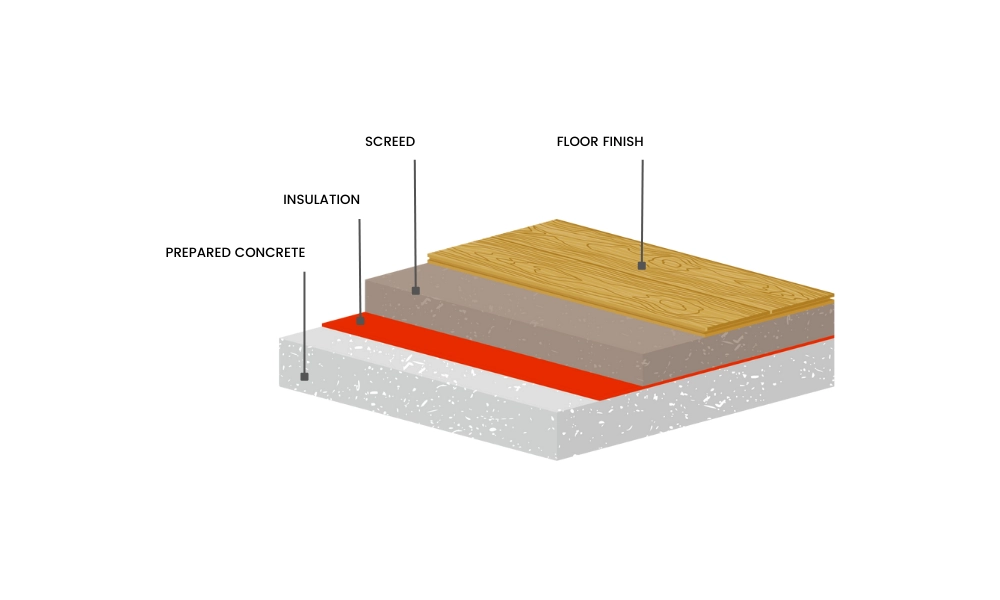

4. Floating Screed

Floating screeds are installed over insulation layers, making them an excellent option for improving thermal efficiency. This type of screed is often used in conjunction with underfloor heating systems or in buildings where soundproofing is required.

Thickness: For cement and sand floating screeds, the typical thickness is 65 mm for light loads and 75 mm for heavy loads. Calcium sulphate floating screeds can be installed as thin as 35 mm in domestic settings or 40 mm in commercial spaces.

Applications: Floating screeds are ideal for improving insulation in residential and commercial buildings, especially when combined with underfloor heating systems.

5. Underfloor Heating Screed

Underfloor heating screeds are specifically designed for use with underfloor heating systems. The screed is applied over the heating pipes or insulation, helping to distribute heat evenly across the floor surface.

- Thickness: Cement and sand screeds typically need to be 65 to 75 mm thick. When reinforced with fibers, this can be reduced to 50 mm. Certain calcium sulphate screeds require just 20 mm of coverage over the heating pipes, bringing the total thickness below 40 mm.

- Advantages: These screeds ensure even heat distribution and prevent hot or cold spots, optimising the performance of underfloor heating systems.

6. Advanced Screed Technologies

Modern advancements in screed technology have introduced high-performance options like Retanol Xtreme, which eliminates the need for curing under polythene and can dry to under 75% relative humidity within three to four days.

- Advantages: This type of screed can be installed at a thickness of just 35 mm for floating screeds and 15 mm for bonded installations. It dries uniformly, reducing the risk of curling or cracking. It also boasts a 60% improvement in heat conductivity, making it ideal for use with underfloor heating systems.

Screed Drying Solutions

For projects where time is of the essence, fast-drying screed solutions are available. At Rapid Energy, we specialise in providing equipment that accelerates screed drying. Our electric boilers can connect directly to your building’s underfloor heating system, helping to speed up the drying process.

For more information and a free, no-obligation quote, feel free to contact our team of experts today.