Drying screed is a crucial phase in the installation of a flooring system. The drying process directly influences the final quality and durability of the floor. In this guide, we’ll cover the different types of screed flooring, discuss screed setting and drying times, debunk common myths, examine variables that affect drying, and explore the types of screed commonly used by UK underfloor heating companies.

Types of Screed Flooring

There are three primary types of screed flooring:

- Traditional Screed: This is a cement, sand, and water mixture typically laid on a concrete subfloor. It’s widely used in both residential and commercial projects.

- Flowing Screed: Known for its self-leveling properties, flowing screed is poured to create a smooth, even surface. It’s popular in modern construction for its ease of installation and finish quality.

- Fast-Drying Screed: As the name suggests, this screed is designed to dry much faster than traditional options, making it ideal for time-sensitive projects.

Screed Setting and Drying Times

- Screed Setting Time: This refers to the time required for the screed to harden enough for foot traffic without causing surface damage. Typically, screed takes 24 to 48 hours to set, depending on the type.

- Screed Drying Time: Full drying time—when the screed is ready for final floor installation—can vary significantly. While some screeds dry in a few days, others may take several weeks. The drying time depends on factors like screed type, thickness, ambient conditions, and the presence of underfloor heating.

Debunking Common Myths About Drying Screed

Several misconceptions persist around the drying of screed:

- Myth: Warm Weather Always Speeds Up Drying

Although warmer temperatures can help, extreme heat can lead to rapid drying, which risks cracking and damaging the screed. - Myth: Opening Windows Speeds Up Drying

While good airflow is important, open windows can introduce fluctuations in temperature and humidity that may slow down the drying process rather than speeding it up.

Variables That Affect Screed Drying Time

Numerous factors influence how long it takes for screed to dry:

- Screed Type: Fast-drying screeds, for example, can dry within 24 hours, while traditional screeds might take up to 28 days.

- Screed Thickness: Thicker layers of screed naturally take longer to dry.

- Environmental Conditions: Ambient temperature and humidity levels can either accelerate or prolong the drying process.

- Ventilation: Proper airflow, balanced with humidity control, is key to a consistent drying pace.

- Underfloor Heating: Using underfloor heating can help reduce drying times by promoting moisture evaporation.

Screed Types Commonly Used by UK Underfloor Heating Companies

Underfloor heating systems have grown in popularity in the UK, and specific types of screed are often used in conjunction with these systems:

- Liquid Screed: This self-leveling screed offers an even finish, ideal for underfloor heating because of its ability to flow around the heating pipes for optimal heat distribution.

- Sand and Cement Screed: A traditional option, this is often laid over concrete and works well with both residential and commercial underfloor heating installations.

- Fast-Drying Screed: Favoured in projects with tight deadlines, fast-drying screed reduces waiting time between installation and the final flooring application.

- Fiber-Reinforced Screed: This type of screed includes added fibres for enhanced strength and flexibility, often used in conjunction with underfloor heating systems to reduce the risk of cracking as the screed expands and contracts with heat.

How Long Does Screed Take to Fully Dry?

Screed drying time varies based on several factors. In general:

- Fast-drying screed: Can dry in as little as 24 hours.

- Traditional screed: May require up to 28 days to fully dry.

The exact time depends on screed thickness, ambient conditions, and the presence of underfloor heating.

Equipment to Speed Up Screed Drying

Waiting for screed to dry can cause delays, but several tools can help speed up the process:

Dehumidifiers: By reducing humidity levels, dehumidifiers accelerate moisture evaporation from the screed, promoting faster drying.

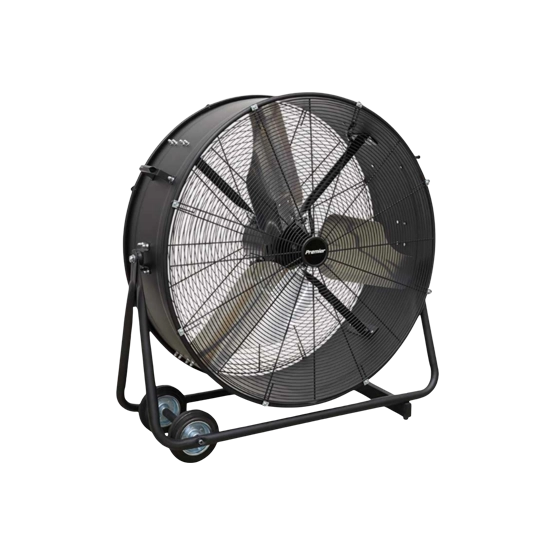

Air Movers (Fans): These industrial fans improve air circulation, speeding up surface moisture evaporation. When used alongside dehumidifiers, the combination of reduced humidity and increased airflow enhances drying speed.

Mobile Electric Boilers: When paired with underfloor heating systems, mobile electric boilers can be used to gently heat the screed. This controlled heat promotes evaporation and speeds up drying, especially in colder climates.

Fast-Drying Screed: A Quick Solution

In addition to using drying equipment, choosing fast-drying screed can drastically reduce drying times. Specially formulated, these screeds incorporate materials that allow for rapid moisture evaporation, making them particularly useful for projects on tight schedules.

Conclusion

Speeding up the screed drying process is achievable with the right tools and screed type. Dehumidifiers, air movers, underfloor heating, and rapid-drying screeds all play a role in reducing drying times. By utilising a combination of these strategies, construction projects can stay on schedule without sacrificing the quality and durability of the final flooring.